How do you perform a Why-Why Analysis using the 5 Whys method? Can you show examples?

Isn’t it amazing to be alive right now? We have answers to almost any question at our fingertips, thanks to the tiny device we carry in our hands. However, even with all these incredible resources, things don’t always go as planned, and we still face problems that puzzle even the best teams. When unexpected challenges pop up, finding the root of the issue can be quite difficult.

But don’t worry—there’s a brilliant method for pinpointing the source of any problem, known as the 5 whys. This technique, used by some of the biggest companies out there, just involves a bit of thinking (and maybe a Lucid chart template). It’s reassuring to know there’s a reliable way to untangle even the trickiest issues!

The beginning of the 5 whys:-

When tackling a problem like this, it becomes less of a hindrance and more of a fascinating exploration. It’s about finding a glimmer of hope even when things seem tough or overwhelming. Take, for instance, the time Ohno utilized the five whys to figure out why a robot stopped working on the assembly floor:

“Why did the robot stop?” The circuit overloaded, causing a fuse to blow.

“Why is the circuit overloaded?” The bearings locked up due to insufficient lubrication.

“Why was there insufficient lubrication on the bearings?” The oil pump wasn’t circulating enough oil to the robot.

“Why isn’t the pump circulating enough oil?” The pump intake is clogged with metal shavings.

“Why is the intake clogged with metal shavings?” There is no filter on the pump.

See how each step brings us closer to uncovering the root cause? It’s like peeling back the layers to get to the heart of the matter.

As shown in the example, the five whys helped Ohno figure out that the team needed to add a filter to the robot’s oil pump. You can use this same method to uncover the root cause and make lasting improvements.

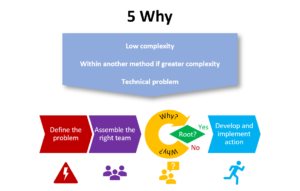

When to use the 5 whys?

The five whys technique is really handy for tackling most issues, especially when they’re fairly straightforward to somewhat challenging. However, when you’re faced with really complicated problems, you’ll notice that the root causes branch out into different areas, each with its own set of root questions. So, think of it this way—trying to understand global poverty by asking just five questions is a bit overwhelming. It’s better to break down big problems into smaller, more manageable pieces and address the root causes of those. The five whys are great for things like manufacturing hiccups, challenges with product launches, team dynamics, or organizational matters.

Hey, if you’re not sure if the five whys method fits the kind of trouble you’re dealing with, it wouldn’t hurt to give it a shot. If you notice that each “why” branches out into separate lines of investigation, you might have a more complicated problem on your hands. In that scenario, trying a cause-and-effect analysis might be a better approach.

Here’s how to perform a 5 Whys analysis:

- Define the Problem: Start by clearly stating the problem or issue you want to investigate.

- Ask “Why?”: Begin by asking “Why did this happen?” and write down the initial answer.

- Repeat “Why?”: For each answer, ask “Why did that happen?” and continue to write down the answers. Repeat this process up to five times, or until you reach a point where further questioning doesn’t provide meaningful insights.

- Identify the Root Cause: Analyze the answers to identify the common themes or patterns, leading to the root cause of the problem.

- 🎓 Discover one of the best Quality assurance courses available — click below to explore the course that’s shaping future QA skills.