What are the standard color codes used for gas cylinders in the pharmaceutical industry?

The standard color codes for gas cylinders in the pharmaceutical industry are crucial for ensuring safety, proper identification, and compliance with regulatory standards. These color codes help users quickly recognize the type of gas within a cylinder, preventing misuse and potential hazards.

1. Purpose of Color Coding

Color coding is used to:

-

Quickly identify the contents of gas cylinders.

-

Enhance safety by reducing the risk of using the wrong gas.

-

Comply with regulatory and international standards (e.g., ISO 32, IS 3933, EN 1089-3).

2. International and National Standards

The color codes may vary slightly depending on the country and regulatory body. Two common standards include:

-

ISO 32 / EN 1089-3 (international)

-

IS 3933 (India-specific)

In the pharmaceutical industry, these standards are often followed in line with Good Manufacturing Practices (GMP) and Occupational Safety and Health Administration (OSHA) guidelines.

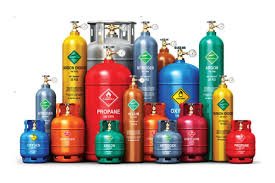

3. Typical Color Codes for Common Gases

Here’s a list of common gases used in pharmaceutical manufacturing and their standard cylinder color codes (as per EN 1089-3 and similar guidelines):

| Gas | Cylinder Body Color | Shoulder Color (Content Indicator) |

|---|---|---|

| Oxygen (O₂) | White | White |

| Nitrogen (N₂) | Black | Black |

| Carbon Dioxide (CO₂) | Grey | Grey |

| Air (Compressed) | Grey | White |

| Helium (He) | Brown | Brown |

| Hydrogen (H₂) | Red | Red |

| Nitrous Oxide (N₂O) | Blue | Blue |

| Ammonia (NH₃) | White | Yellow |

| Chlorine (Cl₂) | Yellow | Yellow |

| Medical Gas Mixtures | Green | Based on gas composition |

🎓 Discover one of the best Quality Assurance courses available — click below to explore the course that’s shaping future QA skills.