SOP for Effluent Treatment Plant .

Standard Operating Procedure (SOP)

1. Purpose

To establish standardized procedures for the operation, maintenance, monitoring, and regulatory compliance of the Effluent Treatment Plant (ETP) to ensure treated effluent meets environmental and safety standards.

2. Scope

This SOP applies to all activities related to the operation and maintenance of the Effluent Treatment Plant (ETP) at [Facility/Organization Name], including effluent intake, treatment processes, discharge, and reporting.

3. Responsibilities

-

ETP Operator: Operate and monitor treatment processes, perform routine inspections, and maintain equipment.

-

Maintenance Team: Ensure that all mechanical, electrical, and automation systems are functioning properly.

-

Environmental Compliance Officer: Monitor compliance with regulatory standards and ensure proper documentation.

-

Plant Supervisor: Oversee daily plant operations, ensure training, and conduct periodic audits.

-

Health & Safety Officer: Ensure safety protocols are adhered to during plant operations.

4. Procedure

4.1 Raw Effluent Intake

-

Monitoring: Check incoming wastewater flow rate and quality. Measure parameters like pH, turbidity, TSS (Total Suspended Solids), BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and temperature.

-

Record Keeping: Document the initial parameters for each shift.

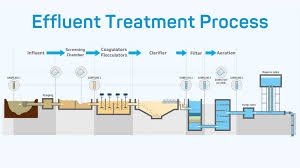

4.2 Pre-Treatment

-

Screening: Remove large solids and debris using bar screens or mesh filters.

-

Oil and Grease Removal: Use oil-water separators to remove excess oils and grease.

-

pH Adjustment: Add acid or alkali to adjust the pH to an optimal range (typically between 6.5–8.5) for subsequent treatment.

4.3 Primary Treatment

-

Sedimentation/Clarification: Use primary clarifiers or settling tanks to remove suspended solids by gravity.

-

Sludge Management: Collect settled sludge and send it to the sludge treatment unit or proper disposal.

4.4 Secondary Treatment

-

Biological Treatment (Activated Sludge Process): Introduce microbial culture to degrade organic pollutants. Maintain aeration tanks for oxygen supply.

-

Clarification: Use secondary clarifiers to separate treated effluent from biological sludge.

4.5 Tertiary Treatment

-

Filtration: Use sand filters, activated carbon filters, or other filtration techniques to remove fine particles.

-

Disinfection: Apply chlorine or UV light to disinfect the treated effluent.

-

Polishing: If necessary, further treat the effluent using additional methods like membrane filtration.

4.6 Monitoring and Sampling

-

Regular Sampling: Collect samples of treated effluent at the discharge point for laboratory analysis.

-

Parameters to Monitor: pH, TSS, BOD, COD, Total Dissolved Solids (TDS), heavy metals, and any specific contaminants based on regulations.

-

Frequency of Sampling: Daily or weekly, as per local regulatory guidelines.

4.7 Effluent Disposal/Discharge

-

Compliance Check: Ensure that the treated effluent meets regulatory standards before discharge.

-

Discharge: Discharge treated effluent to the designated location (e.g., river, drain, or municipal sewer) according to local environmental regulations.

-

Documentation: Maintain records of effluent quality and discharge activities.

4.8 Sludge Handling and Disposal

-

Sludge Dewatering: Use sludge dewatering equipment like centrifuges or belt presses to reduce the volume of sludge.

-

Disposal or Reuse: Transport the dewatered sludge for proper disposal or recycling (e.g., landfill or as a soil conditioner if allowed).

4.9 Emergency Procedures

-

Overflow/Leakage: In case of overflow, shut down affected areas and contain spills using bunds or containment tanks.

-

Equipment Failure: Report equipment failures immediately, and switch to backup systems if available.

-

Regulatory Non-compliance: Immediately report non-compliance of effluent quality to the relevant regulatory authority.

5. Documentation and Record Keeping

-

Treatment Parameters: Record daily measurements and lab results for key parameters.

-

Maintenance Logs: Maintain logs of preventive maintenance, equipment checks, and repairs.

-

Regulatory Reports: Submit regular reports to regulatory agencies as required (monthly, quarterly, or annual).

-

Training Records: Document training sessions for all staff on ETP operations and safety.

6. Safety and Compliance

-

PPE Requirements: Ensure all operators and personnel wear appropriate personal protective equipment (PPE), including gloves, goggles, aprons, and respirators as required.

-

Safety Protocols: Follow safety procedures for handling hazardous chemicals, confined spaces, and electrical systems.

-

Compliance: Ensure adherence to local, regional, and national environmental regulations, including the [insert local environmental regulatory standards].

7. Preventive Maintenance

-

Routine Inspections: Perform regular inspections on pumps, motors, aeration systems, and other critical equipment.

-

Calibration: Regularly calibrate measurement instruments (e.g., pH meters, flow meters).

-

Cleaning: Periodically clean filters, tanks, and pipelines to ensure optimal operation.

8. References

-

Local Environmental Protection Agency (EPA) Regulations

-

ISO 14001 Environmental Management Systems

-

Water Pollution Control Standards

-

Company’s Health & Safety Manual

9. Annexures

-

Effluent Quality Report Template

-

Maintenance Checklist Template

-

Emergency Response Plan.

🎓 Discover one of the best Quality Assurance courses available — click below to explore the course that’s shaping future QA skills.