SOP for Cleaning of Melting Point Apparatus .

Standard Operating Procedure (SOP)

1. Purpose

The purpose of this SOP is to outline the proper cleaning procedure for the Melting Point Apparatus to ensure accurate measurements and maintain the equipment’s proper functioning.

2. Scope

This procedure applies to all laboratory personnel using or maintaining the Melting Point Apparatus in [Department/Organization Name]. It covers routine cleaning after each use and detailed cleaning on a periodic basis.

3. Definitions

-

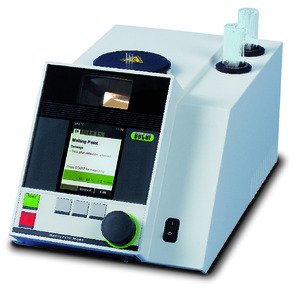

Melting Point Apparatus: A laboratory instrument used to measure the temperature at which a solid substance changes from a solid to a liquid.

-

Cleaning: The process of removing residue, contaminants, or sample material from the apparatus to maintain its integrity and functionality.

4. Responsibilities

-

Operators: Perform cleaning of the Melting Point Apparatus after each use as per this SOP.

-

Supervisors/Managers: Ensure that cleaning is done in accordance with this SOP and that operators are properly trained.

-

Quality Assurance (QA): Periodically audit cleaning processes to ensure compliance.

5. Materials and Equipment

-

Lint-free cloths

-

Isopropyl alcohol or other suitable cleaning solvents

-

Distilled water

-

Soft brushes (non-abrasive)

-

Cleaning brushes (for sample holders)

-

Cotton swabs or pads

-

Laboratory gloves

-

Personal protective equipment (PPE) (e.g., gloves, lab coat, goggles)

6. Procedure

6.1 Safety Precautions

-

Always wear appropriate PPE, including gloves and safety glasses.

-

Ensure that the apparatus is turned off and cooled down before starting the cleaning process.

-

Avoid contact with heated components during and immediately after use to prevent burns.

6.2 Cleaning After Each Use

-

Turn Off and Disconnect Power:

-

Ensure the apparatus is turned off, and disconnect the power supply to avoid any electrical hazards.

-

-

Remove Samples:

-

Carefully remove any samples from the heating chamber or holders using appropriate tools, if necessary.

-

Dispose of any used sample material according to your organization’s waste disposal procedures.

-

-

Clean the Sample Chamber:

-

Use a lint-free cloth or soft brush to gently clean the sample chamber or the viewing area of any residual sample material.

-

If there is any stubborn residue, apply a small amount of isopropyl alcohol to the cloth and wipe the affected area.

-

Ensure that no liquid enters the internal components of the apparatus.

-

-

Clean the Temperature Probe:

-

Gently wipe the temperature probe with a soft cloth dampened with distilled water or isopropyl alcohol.

-

Use a cotton swab for any tight spots, being careful not to damage the probe.

-

-

Clean External Surfaces:

-

Wipe down the external surfaces of the apparatus with a lint-free cloth dampened with a mild cleaning solution or distilled water.

-

Ensure that no cleaning solvents or water enter the internal compartments.

-

-

Dry the Apparatus:

-

After cleaning, ensure all parts are completely dry before use. You can allow the apparatus to air-dry or use a dry lint-free cloth to speed up the drying process.

-

6.3 Periodic Deep Cleaning

-

Frequency of Deep Cleaning:

-

Perform a more thorough cleaning on a scheduled basis (e.g., monthly or quarterly, depending on usage) or when there is a build-up of residue that cannot be removed with routine cleaning.

-

-

Disassemble Components (if applicable):

-

If the apparatus allows for disassembly (e.g., removal of sample holders, temperature probes), carefully remove these components according to the manufacturer’s guidelines.

-

-

Soak Parts (if necessary):

-

For stubborn residue, soak removable components in a cleaning solution or isopropyl alcohol for a few minutes.

-

Use a soft brush or cloth to gently scrub the components to remove any accumulated sample material or other contaminants.

-

-

Inspect for Damage:

-

Inspect the apparatus and components for wear and tear, damage, or contamination that could affect performance.

-

Replace or repair any damaged components according to the manufacturer’s guidelines.

-

-

Reassemble and Test:

-

Reassemble any components that were removed during the deep cleaning process.

-

Perform a quick test run to ensure that the apparatus is working properly.

-

6.4 Special Considerations

-

Avoid Abrasives: Never use abrasive materials (e.g., scouring pads or abrasive brushes) to clean the apparatus, as these can scratch and damage the delicate surfaces.

-

Avoid Harsh Chemicals: Do not use harsh or corrosive cleaning chemicals that could damage the components of the apparatus. Only use solvents and cleaning agents recommended by the manufacturer.

7. Documentation

-

Record each cleaning procedure in the Equipment Maintenance Log. Include:

-

Date and time of cleaning

-

Name of the person performing the cleaning

-

Any observations (e.g., damage, build-up of residue)

-

If a deep cleaning was performed or if parts were replaced

-

8. Precautions

-

Ensure that no cleaning solvent or water enters the internal parts of the Melting Point Apparatus, particularly the electrical components.

-

Do not leave cleaning solvents or alcohol on the apparatus as they may evaporate and leave residues or damage surfaces.

-

Always check that the apparatus is dry before reconnecting it to power or using it for the next measurement.

9. References

-

Manufacturer’s Manual for Melting Point Apparatus

-

Laboratory Safety Guidelines

-

Quality Assurance Policies for Equipment Maintenance

🎓 Discover one of the best Quality Assurance courses available — click below to explore the course that’s shaping future QA skills.