SOP for Calibration Total Organic Carbon (TOC) Analyzer.

Standard Operating Procedure (SOP)

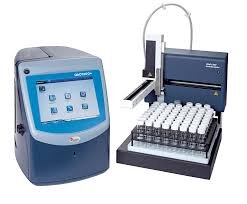

Here is a comprehensive Standard Operating Procedure (SOP) for Calibration of Total Organic Carbon (TOC) Analyzer, which is commonly used in environmental, pharmaceutical, and water quality testing.

1. Objective

To provide a standardized method for the calibration of Total Organic Carbon (TOC) analyzers to ensure accurate and reliable measurements of organic carbon content in water, effluent, or other liquid samples.

2. Scope

This SOP applies to the calibration of all TOC analyzers used in [Company/Laboratory Name], including those employed in the analysis of water samples, pharmaceutical formulations, and environmental monitoring.

3. Responsibilities

-

Analyst/Operator: Perform the calibration, document the results, and troubleshoot any issues.

-

QA/Lead Analyst: Review calibration results, ensuring compliance with SOP and acceptance criteria.

-

Maintenance Team (if applicable): Provide assistance with instrument repair, servicing, and preventive maintenance.

4. Definitions

-

TOC (Total Organic Carbon): The total concentration of carbon in organic compounds in a sample.

-

Calibration Curve: A graph of the instrument response (e.g., peak area) versus known concentrations of TOC.

-

DOC (Dissolved Organic Carbon): The portion of TOC that is soluble in water and can be measured with the TOC analyzer.

-

Precision: The degree of consistency or repeatability of measurements under unchanged conditions.

-

Accuracy: The closeness of the measured value to the true value.

5. Materials and Equipment

-

TOC Analyzer (e.g., Shimadzu, Horiba, or similar)

-

Certified TOC standard solutions (e.g., potassium hydrogen phthalate (KHP) or sodium bicarbonate)

-

Analytical balance (calibrated)

-

Deionized or distilled water (as blank)

-

Syringes, glassware, and containers

-

Calibration logbook or software for documentation

-

Calibration verification standard

6. Procedure

6.1 Instrument Preparation

-

Switch on the TOC Analyzer and allow it to warm up according to the manufacturer’s instructions (usually 30-60 minutes).

-

Check the system for any maintenance issues, such as clogged filters, sample lines, or reagents, and ensure the gas supply (e.g., oxygen) is adequate.

-

Set up the analyzer parameters according to the manufacturer’s guidelines or the specific method being used (e.g., oxidation temperature, sample volume, and type of reagent).

6.2 Preparation of Calibration Standards

-

Prepare a series of calibration standards using certified TOC solutions, such as potassium hydrogen phthalate (KHP) or sodium bicarbonate, at various concentrations covering the expected range of TOC levels (e.g., 1, 5, 10, 25, and 50 mg/L).

-

Ensure all standards are mixed thoroughly and kept in clean, tightly sealed containers.

-

Prepare a blank sample using deionized or distilled water.

6.3 Calibration Procedure

-

Inject the blank sample into the analyzer and record the baseline reading. The blank should ideally have a TOC reading near zero.

-

Inject the first standard solution into the analyzer. Record the TOC value and note the corresponding concentration.

-

Repeat the procedure for each calibration standard (at least 5 standards should be used).

-

Generate a calibration curve by plotting the instrument response (e.g., peak area or absorbance) against the concentration of TOC in the standard solutions.

-

Verify linearity of the calibration curve. The correlation coefficient (r) should be ≥ 0.999 for the calibration to be considered valid.

-

Check calibration accuracy by injecting a verification standard (e.g., a standard at a known concentration) and confirming that the measured value is within ± 10% of the nominal value.

6.4 Calibration Acceptance Criteria

-

Correlation coefficient (r) for the calibration curve should be ≥ 0.999.

-

The measured TOC for the verification standard should be within ± 10% of the expected value.

-

If any standard falls outside the expected range, recalibrate the instrument.

7. Frequency of Calibration

-

Routine Calibration: At least every 6 months or as recommended by the manufacturer.

-

After maintenance, repair, or relocation of the TOC analyzer.

-

Before performing critical analysis (e.g., stability studies, water quality analysis).

-

When discrepancies or out-of-specification results occur.

8. Documentation

-

Calibration Logbook/Software: Document all calibration standards, responses, calibration curve, and verification results.

-

Calibration Report: Include date, instrument ID, standard concentrations, measured TOC, correlation coefficient (r), and any deviations.

-

Out-of-Specification Report: If calibration is not successful, document the issue, troubleshooting steps, and corrective actions taken.

9. Troubleshooting

-

If the calibration curve is not linear: Check for instrument malfunctions, check reagent quality, and ensure proper sample introduction.

-

If the TOC reading is too high or low: Ensure that the sample and reagents are prepared properly, and that the instrument is free from contaminants.

-

If the verification standard fails: Recalibrate the instrument, verify standard accuracy, and check the sample lines for leaks or blockages.

10. Abbreviations

-

TOC – Total Organic Carbon

-

DOC – Dissolved Organic Carbon

-

SOP – Standard Operating Procedure

-

KHP – Potassium Hydrogen Phthalate

-

r – Correlation Coefficient

11. References

-

Manufacturer’s manual for the TOC analyzer

-

ASTM D4839 – Standard Test Method for Total Organic Carbon in Water

-

ISO 8245: Water quality – Determination of the chemical oxygen demand (COD) – Method for TOC measurement

-

ICH Q2(R1) – Validation of Analytical Procedures

🎓 Discover one of the best Quality Assurance courses available — click below to explore the course that’s shaping future QA skills.

https://trcjw.on-app.in/app/oc/306166/trcjw