Case Study: Cross-Contamination in a Multi-Product Pharmaceutical Facility

🧪 Case Study: Cross-Contamination in a Multi-Product Pharmaceutical Facility

📌 Background

A European pharmaceutical manufacturer operated a multi-product solid oral dosage plant. During a routine EMA inspection, regulatory authorities found traces of a potent API (oncology product) in an unrelated antihypertensive batch manufactured in the same facility.

⚠️ Problem

-

Analytical testing of the antihypertensive product showed unexpected peaks in HPLC chromatograms.

-

Laboratory investigations confirmed the presence of the oncology API at trace levels.

-

This indicated cross-contamination between products sharing the same manufacturing lines.

🔍 Root Cause Analysis

-

Cleaning Validation Gaps

-

Inadequate Maximum Allowable Carryover (MACO) calculations.

-

Cleaning validation limits were based on 10 ppm approach rather than toxicological assessment (PDE-based approach).

-

-

HVAC System Deficiency

-

Shared air handling system with insufficient pressure differentials.

-

Inadequate HEPA filtration and poor segregation of production areas.

-

-

Operational Practices

-

Incomplete line clearance procedures.

-

Poor documentation of equipment cleaning.

-

Inadequate staff training on cross-contamination risks.

-

🛠️ Corrective and Preventive Actions (CAPA)

-

Facility Improvements

-

Implemented dedicated HVAC systems for different product categories.

-

Introduced pressure cascade (higher pressure in cleaner areas).

-

-

Cleaning Validation Enhancement

-

Shifted from 10 ppm limits to health-based exposure limits (HBEL / PDE approach) as per EMA guideline (2014).

-

Updated cleaning SOPs and validated worst-case product scenarios.

-

-

Procedural Changes

-

Strengthened line clearance procedures with checklists and independent QA verification.

-

Introduced visual inspection and swab testing before batch release.

-

-

Training & Awareness

-

Conducted refresher training for operators on contamination control strategy (CCS).

-

Introduced periodic mock audits to test compliance.

-

-

Monitoring & Continuous Improvement

-

Routine air monitoring and swab testing included in environmental monitoring.

-

Established risk-based periodic review of cleaning validation data.

-

📈 Outcome

-

Regulatory authority lifted compliance concerns after re-inspection.

-

Company avoided product recall but faced temporary batch quarantines and market delays.

-

Internal culture shifted towards risk-based GMP with stronger emphasis on contamination control.

💡 Key Learning Points

-

Cross-contamination is a patient safety risk — even trace levels of potent compounds can cause harm.

-

Toxicology-based cleaning validation (PDE) is the global regulatory expectation (EMA, WHO, PIC/S, ISPE).

-

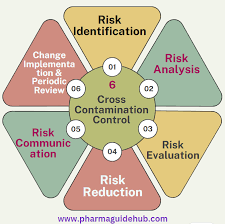

Contamination Control Strategy (CCS) is now required under EU GMP Annex 1 (2023) and applies beyond sterile products.

-

Integrated approach (facility design + procedural controls + training + monitoring) is essential.