Driving Operational Excellence in Pharma: The Role of Gemba Walks

Gemba Walks, a cornerstone of Lean Management, are instrumental in enhancing operational efficiency and quality in pharmaceutical manufacturing. By observing processes directly on the production floor, organizations can identify inefficiencies, engage employees, and foster a culture of continuous improvement.

What Are Gemba Walks?

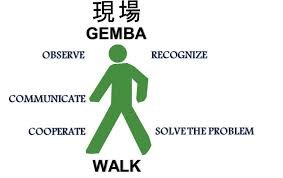

Originating from the Japanese term “Gemba,” meaning “the actual place,” Gemba Walks involve leaders and managers visiting the work area to observe processes, interact with employees, and identify opportunities for improvement. Unlike traditional audits, these walks focus on understanding processes and fostering open communication rather than merely checking compliance.

Implementation in Pharmaceutical Settings

In the pharmaceutical industry, Gemba Walks are applied across various departments, including manufacturing, quality control, and research and development. For instance, Skyepharma integrates Gemba Walks into its lean management practices, with management teams visiting different departments daily to engage with teams, identify best practices, and pinpoint areas for value creation .

Similarly, a global pharmaceutical leader in Germany transitioned from paper-based documentation to a digital platform for Gemba Walks. This shift enabled real-time documentation, immediate assignment of corrective actions, and streamlined reporting, resulting in a 50% reduction in post-walk documentation efforts .

Benefits of Gemba Walks in Pharmaceuticals

-

Enhanced Compliance and Quality: Regular observations help ensure adherence to Good Manufacturing Practices (GMP) and identify deviations promptly.

-

Improved Communication: Direct interactions between management and frontline employees foster a collaborative environment and encourage the sharing of insights.

-

Operational Efficiency: Identifying bottlenecks and inefficiencies leads to streamlined processes and reduced waste.

-

Employee Engagement: Involving employees in problem-solving enhances morale and promotes a culture of continuous improvement.

Case Study: Pharmaceutical Production Facility

A pharmaceutical production facility faced challenges such as equipment setup delays and inconsistent documentation. By implementing Gemba Walks led by cross-functional teams, they achieved a 33% reduction in equipment setup times, decreased documentation errors from 5% to 1.5%, and improved on-time delivery rates from 75% to 92% .

Best Practices for Effective Gemba Walks

-

Structured Approach: Plan walks with specific objectives and focus areas.

-

Employee Involvement: Engage with employees to gain insights and encourage feedback.

-

Real-Time Documentation: Utilize digital tools for immediate recording and action tracking.

-

Follow-Up: Ensure that observations lead to actionable improvements and monitor progress.

In conclusion, Gemba Walks are a vital tool in the pharmaceutical industry’s pursuit of excellence, enabling organizations to enhance quality, efficiency, and employee engagement through direct observation and continuous improvement.

🎓 Discover one of the best Pharmaceutical Quality Assurance course available — click below to explore the course that’s shaping future Quality Assurance skills.