What is Pitot Tube | Insertion flow Meter; Principle, Construction, and Working

📌 Pitot Tube | Insertion Flow Meter

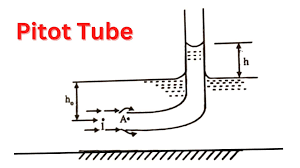

A Pitot tube (also called an Insertion Flow Meter) is a simple, low-cost device used to measure the fluid velocity in pipelines, ducts, or open channels. It works on the principle of differential pressure measurement between stagnation and static pressure points.

🔬 Principle of Pitot Tube

-

Based on Bernoulli’s principle:

-

When fluid strikes the open end of the tube (stagnation point), it comes to rest, and pressure increases (stagnation pressure).

-

At the side openings, fluid continues to flow, showing only static pressure.

-

The difference between stagnation and static pressure = dynamic pressure, which is directly related to fluid velocity.

-

V=2ΔPρV = \sqrt{\frac{2 \Delta P}{\rho}}

Where:

-

VV = Fluid velocity

-

ΔP\Delta P = Pressure difference (stagnation – static)

-

ρ\rho = Fluid density

⚙️ Construction of Pitot Tube

-

Tube: A slender tube with two openings:

-

Front opening → measures stagnation pressure.

-

Side openings → measure static pressure.

-

-

Insertion Mechanism: Tube inserted directly into the pipeline or duct.

-

Manometer/Transmitter: Connected to measure the pressure difference.

-

Support Structure: Mounting arrangements for ducts/pipes.

🔄 Working of Pitot Tube

-

Inserted into the pipeline with its front opening facing the fluid flow.

-

The stagnation pressure is sensed at the front opening.

-

The static pressure is sensed from side holes.

-

The pressure difference is measured using a differential manometer or transmitter.

-

Using Bernoulli’s equation, the fluid velocity is calculated.

-

Multiplying velocity by the cross-sectional area of the pipe gives the volumetric flow rate.

🏭 Applications in Pharmaceuticals & Industry

-

Measuring air velocity in HVAC ducts.

-

Flow measurement in compressed air, steam, and gas lines.

-

Monitoring exhaust air in cleanrooms.

-

Measuring velocity in large pipelines where installing a full-bore flowmeter is not economical.