SOP for Cleaning of Pressure Vessel, Peristaltic Pump and Spraying Gun

Standard Operating Procedure (SOP)

Here is a comprehensive SOP that covers the cleaning of Pressure Vessel, Peristaltic Pump, and Spraying Gun, typically used in pharmaceutical, biotech, or sterile manufacturing environments.

1. Objective

To establish a standardized procedure for cleaning the Pressure Vessel, Peristaltic Pump, and Spraying Gun to ensure removal of residues, maintain hygiene, and prevent cross-contamination.

2. Scope

This procedure applies to all units of Pressure Vessels, Peristaltic Pumps, and Spraying Guns used in manufacturing or sterile operations.

3. Responsibility

-

Operators / Technicians: Execute the cleaning as per this SOP.

-

Production/Engineering Supervisor: Supervise and verify cleaning activities.

-

QA Personnel: Inspect and approve the cleanliness as per GMP requirements.

4. Materials and Equipment Required

-

Purified Water / WFI (as applicable)

Approved non-toxic cleaning detergent

-

Nylon brushes / pipe brushes

-

Lint-free cloths

-

Compressed air (filtered, oil-free)

-

PPE (gloves, gown, mask, goggles)

-

Cleaning Logbook

5. Procedure

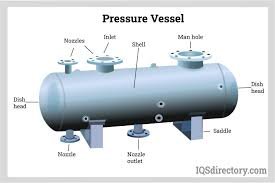

5.1 Cleaning of Pressure Vessel

-

Ensure the vessel is disconnected and depressurized before starting.

-

Wear proper PPE.

-

Drain any residual product and rinse the vessel with purified water.

-

Wash the inner surface using a cleaning solution and a brush or CIP system.

-

Pay attention to weld joints, valves, and manhole seals.

-

Rinse thoroughly with purified water or WFI until no detergent residue remains.

-

Wipe external surfaces with a damp cloth.

-

Dry using lint-free cloth and/or compressed air.

-

Visually inspect and log the cleaning activity.

5.2 Cleaning of Peristaltic Pump

-

Switch off and unplug the pump.

-

Remove and dispose of used tubing per waste procedures.

-

Clean the pump rollers, head, and housing with a damp cloth soaked in detergent solution.

-

Use a soft brush if required to remove residues from crevices.

-

Rinse using purified water (damp cloth or controlled stream).

-

Wipe dry and inspect for cleanliness.

-

Reinstall new or sterilized tubing if ready for next use.

-

Record the cleaning.

5.3 Cleaning of Spraying Gun

-

Disconnect the spraying gun from pressure line or liquid source.

-

Dismantle the spray gun nozzle, pipe, and attachments as per SOP.

-

Rinse with purified water to remove product traces.

-

Soak removable parts in approved cleaning solution.

Soak removable parts in approved cleaning solution. -

Use brushes to scrub nozzle, trigger mechanism, and spray head.

-

Rinse thoroughly with purified water or WFI.

-

Dry using filtered compressed air.

-

Reassemble and check for proper function.

-

Record cleaning details in the logbook.

6. Post-Cleaning Activities

-

Affix “Cleaned” status labels with date, time, and initials.

-

Document all cleaning activities in the Equipment Cleaning Log.

-

Submit for QA inspection and clearance as required.

7. Precautions

-

Avoid excessive moisture near electrical components.

-

Use appropriate tools to dismantle equipment.

-

Do not use harsh or abrasive cleaning agents.

-

Ensure full removal of cleaning agents to prevent contamination.

🎓 Discover one of the best Pharmaceutical Production courses available — click below to explore the course that’s shaping future Production skills.