SOP for Calibration of Conductivity Meter.

Standard Operating Procedure (SOP)

Here’s a sample Standard Operating Procedure (SOP) for the Calibration of a Conductivity Meter. You can tailor this document to fit your organization’s specific requirements or regulatory standards.

1. Purpose

To ensure accurate and reliable readings by calibrating the conductivity meter using standard solutions.

2. Scope

This procedure applies to all conductivity meters used in the laboratory or production areas for quality control purposes.

3. Responsibility

-

QC Analyst: Perform calibration and maintain records.

-

QC Supervisor: Review calibration records and ensure compliance.

-

QA: Audit and verify calibration procedure adherence.

4. Definitions

-

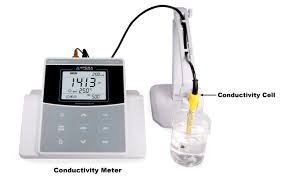

Conductivity Meter: Instrument used to measure the electrical conductivity of a solution.

-

Standard Solution: A solution of known conductivity used for calibration.

5. Materials and Equipment

-

Conductivity meter

-

Calibrated thermometer (for temperature compensation)

-

Conductivity standard solutions (e.g., 84 µS/cm, 1413 µS/cm, 12.88 mS/cm)

-

Distilled or deionized water

-

Clean beakers

-

Lint-free tissues

-

Calibration logbook

6. Procedure

6.1 Preliminary Checks

-

Ensure the conductivity meter is clean and in working condition.

-

Verify the calibration due date of the instrument.

-

Ensure standard solutions are within their expiry date and stored properly.

6.2 Instrument Setup

-

Switch on the instrument and allow it to warm up for at least 5–10 minutes.

-

Select the appropriate range or auto-ranging mode.

6.3 Calibration Steps

-

Rinse the conductivity cell with deionized water, then with a small volume of the standard solution to be used.

-

Immerse the probe in the first standard solution (e.g., 84 µS/cm). Wait for the reading to stabilize.

-

Adjust the reading to match the value on the standard solution label (accounting for temperature if necessary).

-

Repeat the steps with additional standards as needed (e.g., 1413 µS/cm, 12.88 mS/cm) to cover the working range.

-

Record the readings in the calibration log.

6.4 Post-Calibration

-

Rinse the probe with deionized water after calibration.

-

Record the calibration status on the instrument.

-

If calibration fails, inform the supervisor and tag the instrument as “Out of Calibration.”

7. Acceptance Criteria

-

Readings should be within ±2% of the certified value of the standard solution.

-

Calibration must cover the expected range of sample measurements.

8. Frequency of Calibration

-

Daily before use

-

After maintenance or electrode replacement

-

As per manufacturer’s recommendations

9. Documentation

-

Calibration logbook or electronic record

-

Instrument maintenance log

10. References

-

Manufacturer’s instruction manual

-

USP <645> if applicable

-

Internal Quality Manual.

🎓 Discover one of the best Quality Assurance courses available — click below to explore the course that’s shaping future QA skills.