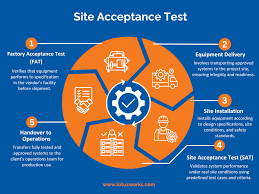

Site Acceptance Test (SAT)

1. Objective

To ensure that equipment, system, or instrument is installed correctly at the user site and performs as per the predefined specifications, operational requirements, and approved protocols.

2. Scope

Applicable to all new equipment, utilities, systems, and instruments installed at the site prior to routine operation and qualification.

3. Responsibilities

-

Vendor/Manufacturer: Perform demonstration, provide required documentation, and support troubleshooting.

-

User Department: Verify installation, review test results, and ensure compliance with specifications.

-

Quality Assurance (QA): Review SAT protocol, witness execution, and approve final SAT report.

-

Engineering: Ensure correct installation and utility connections.

4. Procedure

-

Preparation

-

Review purchase order, user requirement specification (URS), and vendor documents.

-

Ensure utilities (power, water, compressed air, etc.) are available.

-

Prepare SAT protocol.

-

-

Execution

-

Verify physical installation of equipment.

-

Check calibration and verification of instruments/components.

-

Perform functionality tests (start-up, shut-down, alarms, safety features).

-

Confirm software (if applicable) installation and validation.

-

Record observations, deviations, and corrective actions.

-

-

Documentation

-

Record all test results in SAT protocol.

-

Attach vendor manuals, calibration certificates, and test reports.

-

Review and approve SAT report.

-

-

Acceptance Criteria

-

Equipment/system meets URS and specifications.

-

All test results are within acceptance limits.

-

No unresolved deviations.

-

-

Completion

-

Obtain sign-off from Vendor, User, QA, and Engineering.

-

Equipment is released for Installation Qualification (IQ) / Operation Qualification (OQ).

-

5. References

-

User Requirement Specification (URS)

-

Vendor Documentation

-

Regulatory Guidelines