RotaMeter Principle, Working, Construction, and Types

📌 Rotameter

A Rotameter is a simple, reliable device used to measure the flow rate of liquids and gases in pharmaceutical, chemical, and other industries. It belongs to the variable area flowmeter family.

🔬 Principle of Rotameter

-

Works on the variable area principle:

-

A float is placed inside a tapered vertical tube.

-

Fluid enters from the bottom, creating an upward force on the float.

-

The float rises until the upward drag force (fluid flow + buoyancy) balances the downward gravitational force.

-

The float’s stable position indicates the flow rate on a calibrated scale.

-

Equation:

Fg=Fb+FdF_g = F_b + F_d

Where:

-

FgF_g = Weight of float (gravity)

-

FbF_b = Buoyancy force

-

FdF_d = Drag force from fluid flow

⚙️ Working of Rotameter

-

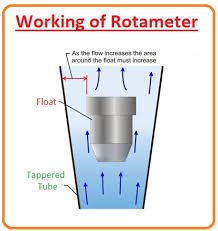

Fluid enters the rotameter from the bottom inlet.

-

The rising fluid pushes the float upwards.

-

As the float moves up, the annular area between the float and tapered tube increases.

-

The increased area allows more fluid to pass, reducing velocity, until forces balance.

-

The float settles at a height proportional to flow rate, which can be directly read on the graduated scale.

🛠️ Construction of Rotameter

-

Tapered Tube: Transparent (glass, acrylic) or metallic, wider at the top than bottom.

-

Float: Made of stainless steel, glass, or plastic; shaped for stable movement.

-

Scale: Calibrated in flow units (L/min, m³/hr, etc.).

-

End Fittings: For inlet/outlet connection to pipeline.

-

Enclosure (optional): For protection in industrial applications.

🔎 Types of Rotameters

-

Glass Tube Rotameter

-

Most common, low cost, transparent tube.

-

Limited to non-corrosive, clear fluids.

-

-

Plastic Tube Rotameter

-

Lightweight, economical, resistant to corrosion.

-

Used in water treatment, pharma utilities.

-

-

Metal Tube Rotameter

-

Rugged, used for opaque, corrosive, or high-pressure fluids.

-

Float position sensed magnetically or electronically.

-

-

Purge Rotameter

-

Small size, used for low flow rates (e.g., purging gas lines).

-

-

Digital/Smart Rotameter

-

Equipped with sensors, transmitters, and digital display.

-

Suitable for integration with SCADA/DCS systems.

-

📌 Applications in Pharmaceuticals

-

Monitoring utility lines (compressed air, nitrogen, water).

-

Flow measurement in purified water (PW), WFI, clean steam systems.

-

Controlling air flow in laminar air flow units and HVAC systems.

-

Monitoring gas flow during fermentation or bioprocesses.

✅ In short:

A Rotameter is a variable area flowmeter that measures flow rate based on float position in a tapered tube. It is simple, reliable, and widely used in pharma, chemical, and water treatment industries.