Good Practices for Air Handling Unit (AHU)

📌 Good Practices for Air Handling Unit (AHU) in Pharmaceuticals

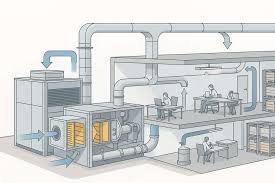

1. Design & Installation

-

AHU must be designed as per GMP & cleanroom classification requirements.

-

Install HEPA/ULPA filters at terminal locations for sterile areas.

-

Provide air locks and pressure differentials to avoid cross-contamination.

-

Use smooth, cleanable surfaces to avoid microbial/particulate accumulation.

2. Operation & Monitoring

-

Maintain differential pressure (10–15 Pa) between areas of different grades.

-

Monitor and record temperature, RH, and differential pressure regularly.

-

Ensure uniform air distribution via proper ducting and diffuser design.

-

Validate and requalify AHUs at defined intervals.

3. Filter Management

-

Pre-filters, fine filters, and HEPA filters must be maintained and replaced as per schedule.

-

Perform integrity testing of HEPA filters (DOP/PAO test).

-

Ensure no bypass or leakages at filter joints.

4. Cleaning & Maintenance

-

Establish SOPs for periodic cleaning of AHU components (filters, coils, ducts, drain pans).

-

Use sanitized condensate drain pans to prevent microbial growth.

-

Calibrate and maintain instruments (differential pressure gauges, sensors).

-

Keep a preventive maintenance schedule for motors, fans, and belts.

5. Documentation & Compliance

-

Maintain logbooks for cleaning, filter changes, calibration, and maintenance.

-

Implement alarm systems for critical parameters (DP, temp, RH).

-

Ensure compliance with EU GMP Annex 1, US FDA, and WHO guidelines.