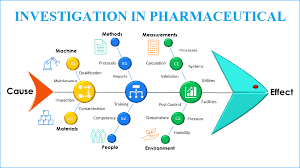

Fishbone Tool of Investigation in Pharmaceuticals

🐟 Fishbone Tool of Investigation in Pharmaceuticals

📌 What is It?

-

A cause-and-effect diagram shaped like a fish skeleton.

-

“Head” = problem statement (e.g., OOS result, contamination, deviation).

-

“Bones” = major categories of potential causes.

-

Helps investigation teams visualize, categorize, and analyze possible root causes systematically.

🧾 Common Categories in Pharmaceutical Investigations

Typically adapted into 6M model (can vary):

-

Man (Personnel)

-

Inadequate training or knowledge.

-

Human error (improper gowning, sampling mistakes).

-

Non-compliance with SOPs.

-

-

Machine (Equipment)

-

Equipment malfunction, improper calibration.

-

Poor preventive maintenance.

-

Design not suitable for cleaning.

-

-

Method (Procedures/SOPs)

-

Inadequate or unclear SOPs.

-

Not followed as written.

-

Lack of proper validation.

-

-

Material (Raw & Packaging)

-

Poor quality of raw materials or excipients.

-

Incorrect labeling or dispensing.

-

Supplier-related variability.

-

-

Measurement (Testing & Data Integrity)

-

Analytical method errors.

-

Incorrect instrument settings.

-

Data integrity lapses.

-

-

Mother Nature (Environment)

-

Environmental contamination (microbial, dust).

-

Temperature/humidity excursions.

-

Poor cleanroom classification or monitoring.

-

🔍 Steps in Using Fishbone for Investigation

-

Define the problem clearly (e.g., “High bioburden in water sample” or “Tablet hardness out of spec”).

-

Brainstorm possible causes under each category.

-

Populate the fishbone diagram with identified causes.

-

Analyze which causes are most likely using data, trend analysis, and evidence.

-

Identify the root cause(s) and link them to CAPA actions.

✅ Benefits in Pharma Investigations

-

Encourages team-based brainstorming.

-

Provides a structured and visual approach to RCA.

-

Ensures no potential cause is overlooked.

-

Strengthens compliance with FDA/ICH Q10 expectations for scientific investigation.

📌 Example Use Cases in Pharma

-

OOS result in HPLC assay.

-

Repeated microbial contamination in cleanroom.

-

Packaging mix-up investigation.

-

Equipment breakdowns affecting batch yield.

🎓 Discover one of the best Complete Pharmaceutical Quality Assurance Course available —click below to explore the course that’s shaping future in QA Course skills.