Calibration of Viscometer

Calibration of Viscometer

1. Introduction

A viscometer is used to measure the viscosity of liquids, which is a critical quality attribute in pharmaceuticals, especially for syrups, suspensions, ointments, creams, and injectable formulations.

Calibration ensures the instrument provides accurate and reproducible viscosity measurements as per manufacturer specifications and pharmacopoeial requirements.

2. Objective

-

To verify that the viscometer readings are within acceptable limits using traceable viscosity standards.

-

To maintain data integrity and comply with GMP/GLP requirements.

3. Principle

Viscosity standards (oils or reference fluids) with known viscosities are measured using the viscometer. The obtained readings are compared with certified values to determine accuracy.

Most pharmaceutical labs use Brookfield viscometers or similar rotational types, where a spindle rotates in the sample, and the resistance to rotation is measured.

4. Equipment & Materials

-

Viscometer (e.g., Brookfield)

-

Certified viscosity standards (NIST-traceable)

-

Calibration bath (to control temperature, typically 25 °C ± 0.1 °C)

-

Stopwatch (if required by method)

-

Clean beakers and spindles

5. Procedure

-

Preparation

-

Switch on the viscometer and allow it to warm up if required.

-

Set temperature control to the calibration temperature (usually 25 °C).

-

Clean and dry the spindle.

-

-

Measure Standard

-

Pour viscosity standard fluid into a clean beaker to the specified volume.

-

Immerse spindle to the correct depth (as per manufacturer’s manual).

-

Set correct speed and spindle type.

-

Allow reading to stabilize and record the viscosity.

-

-

Repeat

-

Perform at least three readings for each standard fluid.

-

Repeat for multiple viscosity ranges if applicable.

-

-

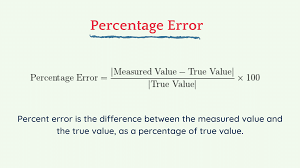

Calculate Accuracy

- Acceptance Criteria

-

Typically ±1% of full scale or as per manufacturer’s specifications.

-

-

Documentation

-

Record standard lot number, temperature, spindle type, speed, measured values, average, % error, and pass/fail status.

-

6. Frequency

-

Before first use

-

At least annually

-

After major repair or relocation

7. References

-

USP <911> Viscosity

-

ISO 2555 (Brookfield method)

-

Manufacturer’s calibration guidelines

-

ICH Q7 & Q10