Calibration of Total Organic Carbon Analyzer

Calibration of Total Organic Carbon (TOC) Analyzer

1. Introduction

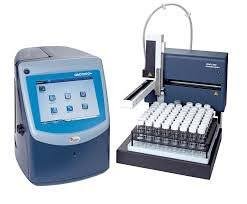

A TOC analyzer is used in pharmaceutical water systems (e.g., Purified Water, WFI) to measure organic contamination. Calibration ensures the instrument accurately detects TOC levels in compliance with USP <643>, EP 2.2.44, and JP requirements.

2. Principle

TOC analyzers work by oxidizing organic carbon in a sample to CO₂, which is then detected (usually via NDIR – Non-Dispersive Infrared). Calibration is done using known standard solutions of sucrose (organic carbon source) and benzoquinone (system suitability test oxidizable compound).

3. Calibration Standards

-

Sucrose Solution: 500 ppb carbon (prepared from certified reference material)

-

Benzoquinone Solution: 500 ppb carbon (prepared from certified reference material)

-

Blank: TOC-free water

4. Procedure

-

Instrument Warm-Up: Allow TOC analyzer to stabilize as per manufacturer’s recommendations.

-

Blank Test: Run TOC-free water to verify baseline stability.

-

Span Calibration: Use sucrose standard to set the high point calibration.

-

System Suitability Test (SST):

-

Inject sucrose (500 ppb C) and record the response.

-

Inject benzoquinone (500 ppb C) and record the response.

-

Calculate % Recovery:

%Recovery=Response of BenzoquinoneResponse of Sucrose×100\% \text{Recovery} = \frac{\text{Response of Benzoquinone}}{\text{Response of Sucrose}} \times 100

-

Acceptance criteria:

-

Sucrose Recovery: 85–115%

-

Benzoquinone Recovery: 85–115%

-

-

-

Linearity Check: Test multiple concentrations (e.g., 100–1000 ppb) to verify linear response.

-

Documentation: Record all results in the calibration logbook/SOP form.

5. Calibration Frequency

-

Initial calibration before first use

-

As per manufacturer’s recommendation (commonly quarterly or semi-annually)

-

After maintenance or repairs

-

When SST fails

6. References

-

USP <643> – Total Organic Carbon

-

EP 2.2.44 – Total Organic Carbon in Water for Pharmaceutical Use

-

ICH Q7 – Equipment Calibration