Calibration of Hardness Tester

Calibration of Hardness Tester in Pharmaceuticals

1. Introduction

Tablet hardness testers are used in pharmaceutical QC labs to measure the crushing strength of tablets, which affects packaging, transport, and dissolution. Regular calibration ensures reliable and reproducible results, complying with GMP and pharmacopoeial standards.

2. Objective

-

To verify that the hardness tester provides accurate readings.

-

To ensure compliance with USP, Ph. Eur., IP, and GLP requirements.

3. Principle

Calibration involves checking the force reading of the tester against a certified reference load or a calibration weight. The device must measure within a defined tolerance range.

4. Equipment Required

-

Certified calibration weights or force gauge (traceable to national standards)

-

Tablet hardness tester (digital or mechanical)

-

Manufacturer’s calibration kit (if applicable)

5. Calibration Procedure

A. Preparation

-

Clean the tester and remove any debris.

-

Switch on and allow warm-up if it’s an electronic model.

B. Steps

-

Zero Adjustment – Ensure the tester reads zero when no load is applied.

-

Apply Reference Load – Place a certified load (e.g., 5 kg, 10 kg) using the calibration kit or weights.

-

Record Readings – Compare displayed value with actual load.

-

Repeat – Test at multiple points across the operational range (low, medium, high).

-

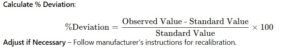

Calculate % Deviation:

Adjust if Necessary – Follow manufacturer’s instructions for recalibration.

6. Acceptance Criteria

-

As per USP <1217> and manufacturer guidelines: ±1% to ±2% of applied load (varies by model).

7. Calibration Frequency

-

Before first use

-

At least once every 6 months

-

After maintenance or repair

8. Documentation

Record:

-

Instrument ID and model

-

Calibration date

-

Applied loads and observed values

-

% deviation

-

Pass/Fail status

-

Analyst and reviewer signatures

References

-

USP <1217> Tablet Breaking Force

-

Ph. Eur. 2.9.8

-

WHO GMP – Laboratory Equipment Calibration