Basics of HVAC System and Its Components

🌬️ Basics of HVAC System in Pharmaceuticals

📌 What is HVAC?

HVAC = Heating, Ventilation, and Air Conditioning.

In pharmaceuticals, HVAC systems are critical to:

-

Maintain controlled environment for manufacturing.

-

Ensure product quality, safety, and regulatory compliance.

-

Provide clean air, temperature, humidity, and pressure control to meet GMP & ISO standards.

📌 Key Functions of HVAC in Pharma

-

Temperature Control – Maintains suitable conditions for product & personnel.

-

Humidity Control – Prevents degradation (e.g., hygroscopic drugs) and microbial growth.

-

Air Cleanliness – Removes particulates & microorganisms using HEPA filters.

-

Airflow Direction & Pressure Differentials – Prevents cross-contamination between clean and less-clean areas.

-

Ventilation – Supplies fresh air and exhausts contaminated air.

⚙️ Major Components of HVAC System

-

Air Handling Unit (AHU)

-

Heart of HVAC.

-

Contains fans, filters, cooling & heating coils.

-

Supplies conditioned, filtered air to cleanrooms.

-

-

Filters

-

Pre-filters – Capture large particles.

-

Fine filters – Remove medium-sized particulates.

-

HEPA filters – Remove ≥99.97% of 0.3 µm particles, essential for sterile areas.

-

-

Ductwork & Dampers

-

Distributes air across rooms.

-

Dampers regulate airflow and maintain pressure differentials.

-

-

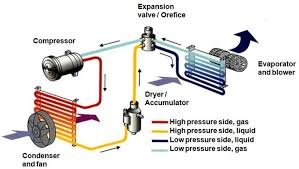

Cooling & Heating Coils

-

Maintain temperature (chilled water or steam systems).

-

-

Blowers / Fans

-

Drive airflow inside ducts and AHU.

-

-

Humidifiers & Dehumidifiers

-

Maintain required relative humidity.

-

-

Terminal HEPA Units / Laminar Air Flow (LAF)

-

Final stage air cleaning at critical points (filling, sampling, weighing).

-

-

Sensors & Monitoring System (BMS/EMS)

-

Continuously monitor temperature, RH, differential pressure, and particle counts.

-

📊 Classification (per ISO 14644 & GMP)

-

Class 100 / ISO 5 – Aseptic filling zones.

-

Class 10,000 / ISO 7 – Support clean areas.

-

Class 100,000 / ISO 8 – Less critical areas like change rooms, corridors.

🎓 Discover one of the best Complete Pharmaceutical Production Course available —click below to explore the course that’s shaping future Production Course skills.