Allergen Control Plan for Pharmaceuticals

🧾 Allergen Control Plan for Pharmaceuticals

1. Risk Assessment

-

Identify allergenic excipients (e.g., lactose, soy lecithin, egg-derived albumin, peanut oil, gluten, gelatin).

-

Assess risk of cross-contamination during manufacturing, packaging, storage, and cleaning.

-

Evaluate suppliers for allergen management in raw materials.

2. Raw Material & Supplier Control

-

Maintain an allergen inventory with details of all incoming materials.

-

Require allergen declarations and certificates from suppliers.

-

Segregate allergen-containing materials in dedicated storage areas with clear labeling.

3. Facility & Equipment Design

-

Where possible, use dedicated equipment and manufacturing areas for allergen-containing products.

-

Apply physical segregation (barriers, color-coded equipment, separate gowning).

-

Maintain proper HVAC systems to prevent airborne cross-contamination.

4. Cleaning & Sanitation Controls

-

Establish validated cleaning procedures to remove allergenic residues.

-

Perform swab testing and analytical verification (e.g., ELISA-based allergen detection).

-

Define “cleaning verification vs cleaning validation” requirements specific to allergens.

5. Production & Handling Practices

-

Schedule allergen-containing product manufacturing at the end of production cycles where feasible.

-

Implement strict line clearance procedures before and after allergen handling.

-

Control waste handling and prevent re-entry of contaminated materials.

6. Personnel Practices

-

Train employees on allergen awareness, handling, and prevention of cross-contact.

-

Use dedicated gowns, gloves, and tools when working with allergenic materials.

-

Ensure proper hygiene and gowning procedures before moving between production areas.

7. Labeling & Documentation

-

Clearly label allergen-containing materials and products at every stage.

-

Ensure patient information leaflets and packaging mention allergenic excipients as per regulatory requirements (e.g., lactose intolerance, peanut oil warnings).

-

Maintain traceability records for allergen management.

8. Deviation, CAPA & Monitoring

-

Investigate any allergen cross-contamination incident as a critical deviation.

-

Implement Corrective and Preventive Actions (CAPA) with root cause analysis.

-

Periodically audit allergen control practices and update risk assessments.

9. Regulatory Compliance

-

Align with ICH Q9 (Quality Risk Management), EU EMA excipient guidelines, US FDA labeling requirements, and WHO GMP expectations.

-

Ensure compliance with local pharmacopeia labeling requirements for allergens.

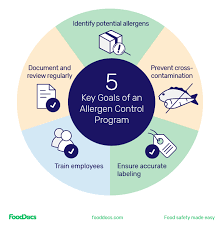

📌 Key Benefits of an Allergen Control Plan

-

Prevents patient safety risks (hypersensitivity, anaphylaxis).

-

Reduces risk of regulatory non-compliance and recalls.

-

Supports data integrity and transparency in product labeling.

-

Enhances patient trust and product quality.

🎓 Discover one of the best Complete Pharmaceutical Quality Assurance Course available —click below to explore the course that’s shaping future in QA Course skills.