HEPA Filter uses in Pharmaceutical manufacturing

📌 HEPA Filter Uses in Pharmaceutical Manufacturing

🔬 What is a HEPA Filter?

-

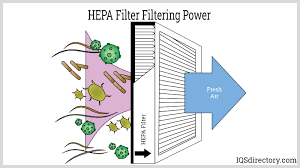

High Efficiency Particulate Air (HEPA) Filter removes ≥ 99.97% of airborne particles ≥ 0.3 microns.

-

Essential for cleanroom design and controlled environments.

✅ Uses in Pharmaceutical Manufacturing

-

Cleanroom Classification & Control

-

Maintains ISO/GMP cleanroom grades (A, B, C, D).

-

Ensures particle-free environment for sterile manufacturing.

-

-

Aseptic Processing & Sterile Area

-

Provides unidirectional airflow (LAF, RLAF, Biosafety Cabinets).

-

Prevents contamination of sterile injectables, ophthalmics, biologics, etc.

-

-

HVAC Systems in Pharma

-

Installed in Air Handling Units (AHU) for terminal filtration.

-

Ensures clean, filtered air supply to manufacturing and packing areas.

-

-

Sampling & Dispensing Booths

-

Protects product and operator during handling of APIs, powders, and raw materials.

-

-

Microbiology & QC Labs

-

Used in biosafety cabinets and clean benches for aseptic testing.

-

-

Containment of Hazardous Substances

-

Prevents release of toxic dust or potent drug particles (oncology, hormones).

-

-

Regulatory Compliance

-

Required by US FDA, EU GMP, WHO TRS, and ISO 14644 for sterile drug manufacturing.

-

📌 In Summary

HEPA filters are critical barriers in pharmaceutical manufacturing for contamination control, aseptic processing, operator protection, and regulatory compliance.