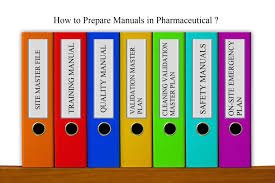

Guidelines for Preparation of Site Master File (SMF)

🏭 Guidelines for Preparation of Site Master File (SMF)

📑 1. General Information

-

Company name, address, and contact details.

-

Name of parent company (if applicable).

-

Manufacturing activities performed at the site.

-

Products handled (human, veterinary, APIs, biologicals, etc.).

-

Manufacturing license and regulatory approvals.

-

Organizational structure with key personnel and their qualifications.

🏢 2. Quality Management System (QMS)

-

Description of QMS and its scope.

-

Management responsibilities and GMP policy.

-

Procedures for handling deviations, OOS, OOT, and CAPA.

-

Change control system.

-

Internal audit/self-inspection system.

-

Product quality review (PQR) process.

👩🔬 3. Personnel

-

Organization chart (QA, QC, Production, Engineering).

-

Key personnel responsibilities (Head QA, Head QC, Production Manager).

-

Training systems (GMP, safety, technical).

-

Health and hygiene requirements (medical checks, gowning, restrictions).

🏭 4. Premises & Facilities

-

Site layout and floor plans (flow of materials and personnel).

-

Production areas (oral, sterile, non-sterile, packaging).

-

Storage areas (quarantine, released, rejected, returned, cold rooms).

-

Ancillary areas (change rooms, cafeterias, offices).

-

Utilities: water systems (PW, WFI), HVAC, compressed air, cleanrooms.

-

Pest control measures.

⚙️ 5. Equipment

-

List of major equipment used in production and QC.

-

Qualification and calibration practices.

-

Cleaning and preventive maintenance systems.

-

Status labeling (Cleaned, In-Use, Out of Service).

📦 6. Documentation

-

System for SOPs, records, logbooks, batch records.

-

Document control, approval, and archival.

-

Data integrity policy (audit trails, electronic systems).

🧪 7. Production

-

Types of products manufactured.

-

Flowcharts for manufacturing processes (e.g., tablet, capsule, injection).

-

Cross-contamination control measures.

-

Handling of starting materials, intermediates, and finished products.

-

Packaging and labeling controls.

🧫 8. Quality Control (QC)

-

Description of QC laboratory facilities.

-

List of instruments (HPLC, GC, UV, etc.).

-

Sampling procedures.

-

Specifications, reference standards, and reagents handling.

-

Stability testing program.

🚚 9. Storage, Distribution & Complaints

-

Storage practices (temperature, humidity monitoring, FEFO/FIFO).

-

Transportation and cold chain control.

-

Complaint handling procedure.

-

Recall system (mock recalls, effectiveness checks).

♻️ 10. Validation & Qualification

-

Master Validation Plan (MVP).

-

Process validation, cleaning validation, analytical method validation.

-

Equipment/utility qualification (DQ/IQ/OQ/PQ).

-

Computerized system validation.

🔒 11. Contract Activities

-

Details of contract manufacturers, laboratories, and service providers.

-

Technical/quality agreements.

-

Oversight and audits of contractors.

🧾 12. Other Relevant Information

-

Handling of returned, rejected, and recalled products.

-

Handling of counterfeit or falsified medicines.

-

Product security and data protection measures.

-

Environmental, health, and safety measures.

📌 Key Notes for SMF Preparation

-

Keep it concise (25–30 pages max) – provide summaries, not full SOPs.

-

Include flowcharts, diagrams, and layouts for clarity.

-

Ensure consistency with actual practices (inspectors will verify on-site).

-

Review and update regularly (at least annually or after major changes).

🎓 Discover one of the best Complete Pharmaceutical Quality Assurance Course available —click below to explore the course that’s shaping future in QA Course skills.