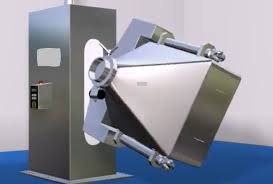

SOP for Cage Blender

1.0 Purpose

To lay down the procedure for operation, cleaning, and maintenance of the Cage Blender to ensure uniform mixing of powders and granules in compliance with cGMP.

2.0 Scope

This SOP applies to the Cage Blender installed in the production area of [Company Name], used for blending pharmaceutical raw materials and granules.

3.0 Responsibility

-

Production Operator: To operate and clean the Cage Blender.

-

Production Supervisor: To verify operations, cleaning, and log entries.

-

Engineering: To perform preventive maintenance and repairs.

-

Quality Assurance (QA): To check line clearance and cleaning verification.

4.0 Definitions

-

Cage Blender (Bin Blender/IBC Blender): A blender designed to hold an Intermediate Bulk Container (IBC) or bin, which rotates in different directions to ensure uniform mixing of powders or granules.

5.0 Procedure

5.1 Operation

-

Ensure equipment has a “Cleaned” status label and line clearance is approved by QA.

-

Load the required quantity of material into the IBC/bin as per BMR.

-

Seal the IBC/bin with lid and fix clamps securely.

-

Place the IBC/bin into the blender cage and lock it properly.

-

Set the required blending parameters:

-

Speed (rpm)

-

Time (minutes)

-

-

Close safety guards and ensure interlocks are functional.

-

Start the blender and allow it to run for the specified cycle.

-

After completion, stop the blender and unlock the bin.

-

Transfer the blended material for further processing.

-

Record details in the equipment usage logbook.

5.2 Cleaning

Type A – Batch-to-Batch Cleaning

-

Switch OFF the power supply.

-

Remove the bin/IBC from the cage.

-

Wipe cage and clamps with a dry lint-free cloth.

-

If required, clean bin external surfaces with purified water and dry.

Type B – Product Changeover Cleaning

-

Perform all steps of Type A cleaning.

-

Clean the cage, clamps, and non-contact parts with 70% IPA.

-

Ensure no product residues are present in/around the cage.

-

QA to verify before next product use.

Type C – Weekly / Periodic Cleaning

-

Clean cage body, guards, and drive components externally.

-

Inspect for wear, rust, or damage.

5.3 Maintenance

-

Preventive maintenance shall be performed as per engineering schedule.

-

Check gearbox, motor, bearings, and limit switches.

-

Inspect safety interlocks and guards for functionality.

-

Lubricate moving parts as recommended by manufacturer.

-

Record all activities in equipment history log.

6.0 Safety Precautions

-

Do not operate blender without securing the bin.

-

Ensure safety guards are in place before starting.

-

Never insert hands or tools into blender cage during operation.

-

Disconnect power before cleaning or maintenance.

-

Wear gloves, mask, and protective gear while operating.

7.0 Documentation

-

Equipment usage logbook

-

Cleaning record

-

Preventive maintenance record

8.0 References

-

Manufacturer’s operating manual

-

cGMP guidelines

-

Batch Manufacturing Record (BMR)

9.0 Abbreviations

-

SOP: Standard Operating Procedure

-

BMR: Batch Manufacturing Record

-

IBC: Intermediate Bulk Container

-

cGMP: Current Good Manufacturing Practices

-

IPA: Isopropyl Alcohol

🎓 Discover one of the best Complete Pharmaceutical Production Course available —click below to explore the course that’s shaping future Production Course skills.