Tablet Manufacturing Process: An Overview

🔹 Tablet Manufacturing Process: An Overview

Tablets are solid dosage forms containing one or more active pharmaceutical ingredients (APIs) with suitable excipients. The manufacturing process must ensure uniformity, stability, safety, and efficacy.

1. Pre-Formulation Studies

-

Study of API properties: solubility, stability, particle size, flow, compressibility.

-

Selection of excipients: diluents, binders, disintegrants, lubricants, glidants, coating materials.

-

Goal: Identify a suitable formulation strategy (direct compression, wet granulation, or dry granulation).

2. Formulation Approaches

There are three main manufacturing methods:

a) Direct Compression

-

Blend API + excipients → directly compressed into tablets.

-

Advantages: Simple, fast, cost-effective, fewer steps.

-

Limitations: Requires API with good flow and compressibility.

b) Wet Granulation

-

API + excipients mixed → binder solution added → wet mass formed → granulated → dried → sized → lubricated → compressed.

-

Advantages: Improves flow, compressibility, and content uniformity.

-

Limitations: Moisture/heat-sensitive drugs not suitable.

c) Dry Granulation (Slugging or Roller Compaction)

-

API + excipients compacted into slugs/compacts → milled → blended with lubricant → compressed.

-

Advantages: Suitable for moisture/heat-sensitive drugs.

-

Limitations: Higher cost, may have lower tablet strength than wet granulation.

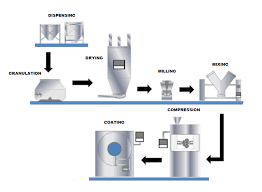

3. Unit Operations in Tablet Manufacturing

Step 1: Weighing and Dispensing

-

Accurate weighing of API and excipients in dispensing booth (to prevent cross-contamination).

Step 2: Blending / Mixing

-

Ensures uniform distribution of API with excipients.

-

Performed in V-blenders, double-cone mixers, or bin blenders.

Step 3: Granulation (if applicable)

-

Wet granulation: Uses fluid bed granulator or high-shear granulator.

-

Dry granulation: Uses roller compactor.

Step 4: Drying

-

Removes moisture from wet granules (fluid bed dryer, tray dryer).

-

Aim: Achieve optimal residual moisture for flow and compressibility.

Step 5: Milling / Sizing

-

Break down oversized granules, ensure uniform particle size.

Step 6: Final Blending / Lubrication

-

Add lubricants (e.g., magnesium stearate), glidants (colloidal silica), disintegrants.

Step 7: Compression

-

Granules or blends compressed into tablets using rotary or single-punch tablet press.

-

Parameters: hardness, thickness, weight, friability.

Step 8: Tablet Coating (optional)

-

Film coating: Thin polymeric layer for protection, taste masking, controlled release.

-

Sugar coating: Traditional, thicker, less common now.

-

Enteric coating: Protects drug from stomach acid.

Step 9: Packaging

-

Blister packs, bottles, or strips under controlled conditions.

-

Ensures stability, patient compliance, tamper resistance.

4. In-Process & Quality Control

-

Blend uniformity

-

Granule flow, bulk/tapped density

-

Tablet weight variation, hardness, friability, disintegration, dissolution

-

Content uniformity, assay, microbial limits

-

Visual inspection for defects (chipping, capping, picking, lamination).

5. Key Considerations

-

Compliance with GMP, ICH, and pharmacopeial standards (USP, EP, IP).

-

Critical Process Parameters (CPPs) must be controlled to achieve desired Critical Quality Attributes (CQAs).

-

Process Analytical Technology (PAT) and Quality by Design (QbD) approaches increasingly applied.

✅ Summary

The tablet manufacturing process involves:

-

Pre-formulation & formulation development

-

Blending, granulation, drying, sizing, and lubrication (depending on method)

-

Compression and coating

-

Packaging & QC testing

The chosen method (direct compression, wet granulation, dry granulation) depends on the API properties and product requirements.

🎓 Discover one of the best Complete Pharmaceutical Production Course available —click below to explore the course that’s shaping future Production Course skills.

https://trcjw.on-app.in/app/oc/338669/trcjw