Reynolds Number and Its Significance in Purified Water System

Reynolds Number and Its Significance in Purified Water System

1. What is Reynolds Number?

-

Reynolds number (Re) is a dimensionless number that predicts the flow regime of a fluid (laminar, transitional, or turbulent).

-

Formula:

Where:

-

ρ = Fluid density (kg/m³)

-

v = Velocity of fluid (m/s)

-

D = Pipe diameter (m)

-

μ = Dynamic viscosity of fluid (Pa·s)

2. Flow Regimes

-

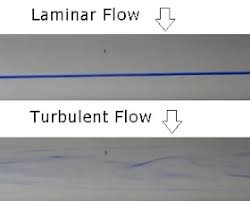

Laminar flow (Re < 2000): Fluid moves in parallel layers with little mixing.

-

Turbulent flow (Re > 4000): Fluid has chaotic mixing and uniform velocity profile.

-

Transitional flow (2000 < Re < 4000): Unstable zone between laminar and turbulent.

3. Significance in Purified Water Systems

-

Microbial Control

-

Turbulent flow (Re > 4000) ensures proper mixing and minimizes biofilm formation on inner pipe surfaces.

-

Laminar flow allows stagnation zones where microorganisms can attach and multiply.

-

-

System Design

-

PW and WFI distribution loops are designed to maintain turbulent flow velocity ≥ 1.0–1.5 m/s (depending on pipe diameter).

-

Ensures effective scouring action of water against pipe walls.

-

-

Validation & Qualification

-

During system qualification, Reynolds number calculations confirm that piping design and pumps maintain turbulent flow.

-

Regulatory agencies (FDA, EMA, WHO) expect turbulent conditions to ensure microbiological quality.

-

-

Operational Monitoring

-

Continuous monitoring of flow velocity and return flow ensures system stays within design limits.

-

Helps in early detection of flow disruptions or pump failures.

-

4. Practical Example

-

Suppose purified water (ρ ≈ 1000 kg/m³, μ ≈ 0.001 Pa·s) flows at 1.2 m/s in a pipe of 0.05 m diameter:

Re=0.0011000×1.2×0.05=60,000

→ This indicates turbulent flow (well above 4000), ensuring microbial control.

✅ In short:

Reynolds Number helps determine whether purified water in distribution loops flows turbulently, which is essential for preventing biofilm formation, ensuring microbial control, and complying with GMP design standards.

🎓 Discover one of the best Pharmaceutical Microbiology course available —click below to explore the course that’s shaping future Microbiology course skills.