Criteria to Choose the Correct Swab for Cleaning Validation

Criteria to Choose the Correct Swab for Cleaning Validation

Cleaning validation in pharmaceuticals ensures that residues from previous products, cleaning agents, or contaminants are effectively removed from manufacturing equipment to prevent cross-contamination.

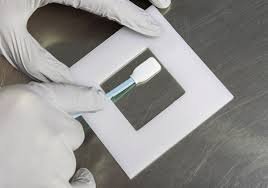

Swab sampling is a widely used method, and selecting the correct swab is essential for reliable and reproducible results.

1. Material Compatibility

-

Swab tip should not react with residues, solvents, or analytes.

-

Common materials:

-

Polyester or microfiber: Low background, compatible with aqueous and organic solvents.

-

Polypropylene or nylon: Chemically inert and durable.

-

Avoid cotton (can leave fibers or interfere with analysis).

-

2. Low Background Contamination

-

Swab must have minimal extractables and leachables.

-

Should not release interfering substances that affect analytical results (e.g., in HPLC or TOC testing).

3. Mechanical Strength & Abrasion Resistance

-

Strong enough to scrub surfaces without breaking or shedding fibers.

-

Must allow consistent pressure during sampling.

4. Size & Shape

-

Swab tip and handle should allow access to hard-to-reach areas (e.g., corners, crevices, valves).

-

Flat, round, or pointed tips may be selected depending on equipment geometry.

5. Absorption & Recovery Efficiency

-

Must absorb residues effectively.

-

Good recovery efficiency for targeted contaminants (validated using recovery studies).

6. Compatibility with Cleaning Validation Solvent

-

Should be compatible with chosen extraction solvent (e.g., water, methanol, isopropyl alcohol).

-

Swab should not degrade or swell in solvent.

7. Sterility (if required)

-

For aseptic or sterile manufacturing areas, sterile swabs should be used to avoid introducing microbial contamination.

8. Handle Material

-

Should be chemically inert, sturdy, and compatible with cleaning agents.

-

Plastic or polypropylene handles are preferred over wood (to avoid contamination).

9. Regulatory & GMP Compliance

-

Swabs should comply with USP, EP, or other applicable pharmacopeial standards.

-

Must have vendor qualification and Certificate of Analysis (CoA).

✅ Summary for Selection:

Chemically inert → Low background → Durable → Right size/shape → High recovery efficiency → Solvent-compatible → Sterile if needed → GMP compliant

🎓 Discover one of the best Pharmaceutical Quality Assurance course available —click below to explore the course that’s shaping future Quality Assurance skills.

https://trcjw.on-app.in/app/oc/306166/trcjw