Gemba Walks and Its implementation in Pharmaceuticals

Gemba Walks and Their Implementation in Pharmaceuticals

1. What is a Gemba Walk?

-

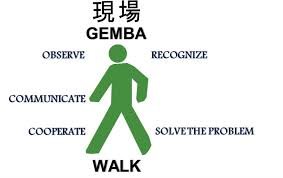

Gemba is a Japanese term meaning “the real place”—where work actually happens.

-

In lean manufacturing and quality management, a Gemba Walk is when leaders, managers, or QA personnel go to the shop floor to observe processes, engage with employees, and identify improvement opportunities.

-

In pharmaceuticals, this typically means visiting manufacturing, packaging, laboratory, or warehouse areas.

2. Objectives of a Gemba Walk in Pharma

-

Ensure GMP compliance is being followed.

-

Observe processes to identify waste, inefficiencies, and safety risks.

-

Strengthen communication between operators and management.

-

Promote a culture of continuous improvement and data integrity.

3. Steps for Effective Gemba Walk Implementation

Step 1: Define the Purpose

-

Clarify the objective: compliance check, process improvement, safety audit, or training.

Step 2: Schedule and Prepare

-

Choose frequency: daily, weekly, or monthly.

-

Review relevant SOPs, previous audit findings, and KPIs before visiting.

Step 3: Go to the Gemba

-

Visit the actual workplace.

-

Observe processes without interrupting unnecessarily.

-

Use checklists to guide observations (GMP, safety, hygiene, documentation practices).

Step 4: Engage with Employees

-

Ask open-ended questions:

-

“Can you walk me through your process?”

-

“What challenges do you face here?”

-

-

Build trust—focus on learning, not blaming.

Step 5: Identify Opportunities for Improvement

-

Look for:

-

Documentation gaps

-

Deviations from SOPs

-

Equipment issues

-

Material handling risks

-

Safety hazards

-

Step 6: Record Observations

-

Document:

-

Date, time, area visited

-

Observations (good practices + non-conformances)

-

Photos or diagrams (if allowed by SOPs)

-

Immediate actions taken

-

Step 7: Follow-Up and CAPA

-

Convert significant findings into deviations, change controls, or CAPA.

-

Assign responsibilities and timelines for implementation.

4. Key Considerations for GMP Compliance

-

Gemba Walks must respect cleanroom entry protocols and gowning procedures.

-

Observers must avoid cross-contamination risks.

-

Data and observations must comply with ALCOA+ principles.

-

Findings should feed into Management Review & Continuous Improvement programs.

5. Benefits in Pharmaceuticals

-

Early detection of compliance gaps.

-

Improved operational efficiency.

-

Better employee engagement and morale.

-

Strengthened quality culture.

-

Supports readiness for regulatory inspections.

Summary Flow:

Plan → Observe → Engage → Identify Issues → Document → Implement CAPA → Review Effectiveness

🎓 Discover one of the best Pharmaceutical Quality Assurance course available —click below to explore the course that’s shaping future Quality Assurance skills.

https://trcjw.on-app.in/app/oc/306166/trcjw