4 Steps to Effective Change Control in Pharmaceuticals

4 Steps to Effective Change Control in Pharmaceuticals

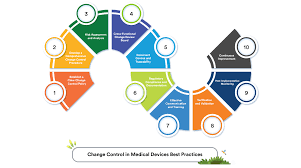

1. Initiation & Documentation

-

Identify the need for change (equipment, process, material, method, etc.).

-

Document the proposed change in a Change Control Form with details like scope, reason, impact area, and requester details.

2. Impact Assessment

-

Evaluate potential effects on product quality, safety, efficacy, regulatory compliance, and validation status.

-

Involve cross-functional teams (QA, QC, Production, Regulatory, Engineering).

-

Decide if change is minor, major, or critical.

3. Approval & Implementation

-

Obtain formal approval from the Change Control Committee (CCC) or QA head.

-

Plan implementation steps, timelines, and resources.

-

Train relevant personnel before execution.

4. Verification & Closure

-

Verify that the change has been implemented as approved.

-

Perform post-change testing, validation, or qualification if needed.

-

Close the change control with final QA sign-off and retain all documentation for audit purposes.

✅ Key Principle: Every change must be controlled, documented, risk-assessed, approved, and verified to maintain GMP compliance.